- Home

- News & Events

- News

Laser-Based Radioactive Waste Cleaning Technology Tested for the First Time at the Ignalina Nuclear Power Plant

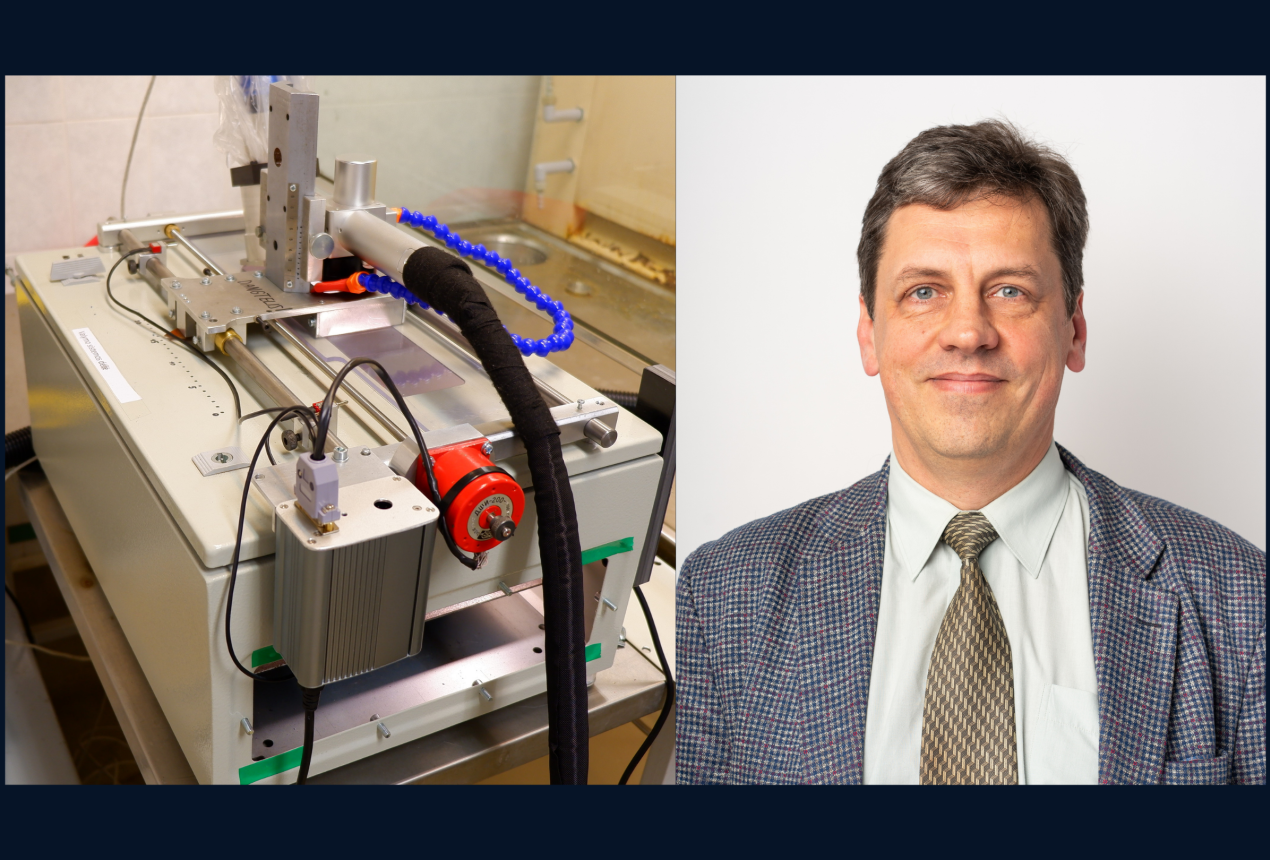

Scientists from the Center for Physical Sciences and Technology (FTMC) have carried out the first practical trials of a unique laser technology designed for cleaning radioactive waste at the Ignalina Nuclear Power Plant. The main goal of these tests is to determine whether laser cleaning could become a reliable alternative to existing decontamination methods and to assess its efficiency in removing radionuclide contamination from metal surfaces.

“FTMC researchers have been contributing to enhancing the safety of the Ignalina Nuclear Power Plant for more than 20 years, providing scientific and expert support in the dismantling of nuclear facilities as well as in the characterisation and management of radioactive waste. This study of laser technology will help evaluate what proportion of radioactive contaminants can be removed and safely captured by the filtration system, thereby reducing both the volume and the hazard level of radioactive waste,” says Dr Artūras Plukis, Head of the FTMC Department of Nuclear Research.

“We aim to improve radioactive waste decontamination and management processes, which is why we actively seek new, advanced methods. The use of laser technologies is a promising and rapidly developing direction in global radioactive waste management. Lithuania is internationally recognised as a leader in laser technologies, so by collaborating with scientists in this field, we seek to transform this potential into practical solutions for managing the nuclear legacy. Our goal is to increase radioactive waste conversion rates and return cleaned materials to the consumption cycle – one of our key sustainability commitments,” says Linas Baužys, Head of the Ignalina Nuclear Power Plant, operating under the name Altra.

According to Baužys, these trials open new opportunities not only for the radioactive waste decontamination process at Ignalina, but also for Lithuanian laser technology companies. “Once this decontamination technology is tested and developed here, Lithuanian companies will be able to successfully offer this service or laser equipment to other nuclear energy countries that are also seeking innovative solutions. Currently, around 200 nuclear reactors worldwide have reached the end of their operational lifetime, meaning that the competencies of Lithuania’s laser sector could be applied on a much broader scale than just the Ignalina project,” he notes.

(The Ignalina Nuclear Power Plant, 2020. Photo: Gregorio Nuti / Unsplash.com)

The Ignalina Nuclear Power Plant has already achieved high waste conversion rates – 78% of dismantled equipment and as much as 94% of reinforced concrete have been successfully released from radiological control and can be passed on to the secondary raw materials market. Laser-based radioactive waste cleaning could become an important innovation contributing to the modernisation and increased efficiency of decontamination processes.

One of the major advantages of laser decontamination is the minimal amount of secondary waste generated. Currently, decontamination is most often carried out using high-pressure water jets, which create secondary liquid radioactive waste, or in specialised shot-blasting equipment, which produces contaminated metal shavings. Using laser technology generates only additional aerosols, which are collected and filtered, significantly reducing the quantity of secondary waste.

During the laser technology testing experiment, FTMC scientists analysed which types of waste generated at the nuclear facility are suitable for laser decontamination, selected the parameters of the laser cleaning system, and carried out prototype tests under real conditions in the plant’s premises. To objectively assess the efficiency of the laser technology, various samples from the Ignalina Nuclear Power Plant were tested – differing in metal type, shape, and radioactive contamination level.

After evaluating the test results, FTMC researchers will prepare recommendations for applying laser technology in the decontamination processes at the Ignalina Nuclear Power Plant. The experiment’s conclusions are expected next April, with final recommendations due in June. Implementing innovative technologies such as laser cleaning may significantly contribute to the continued effective decommissioning of the nuclear power plant.

The project “Lazerinės technologijos branduolinės energetikos objektuose susidariusioms radioaktyviosioms atliekoms dezaktyvuoti” (“Laser Technologies for Decontaminating Radioactive Waste Generated at Nuclear Facilities”) is being carried out by Altra and the Center for Physical Sciences and Technology in cooperation with the Research Council of Lithuania.